Categories

- Our Blog (57)

- Our Projects (62)

- FAQ (6)

**Key Differences Between the 2 Solutions

for Lithium Battery Module: FPC/CCS

Solution and Traditional Wiring Harnesses**

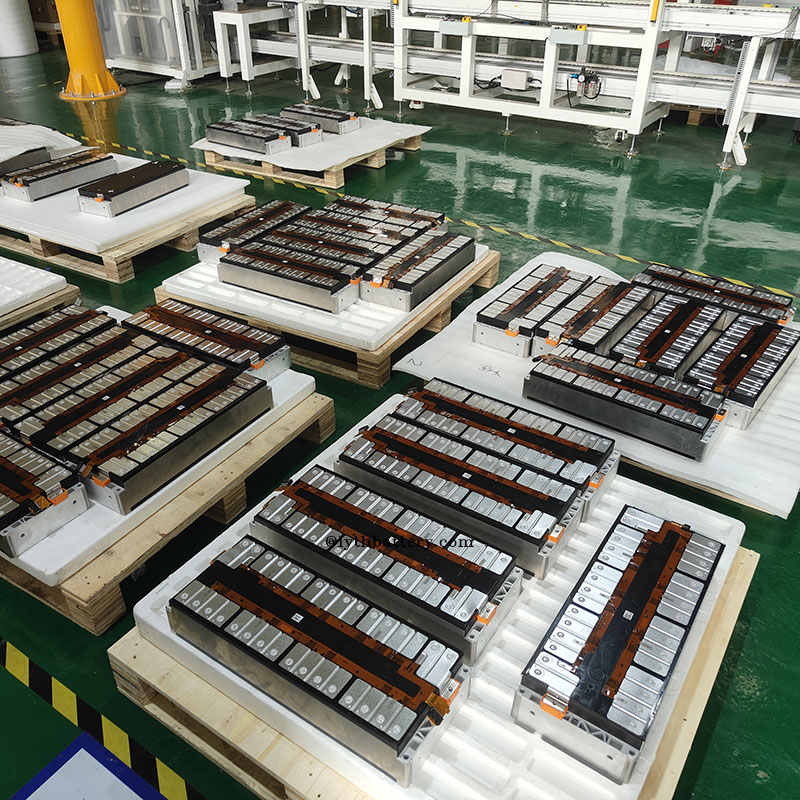

In the rapid development of new energy vehicles, the battery module, as a core component of the power system, has undergone a significant transition from traditional wiring harnesses to flexible printed circuits (FPC/CSS solution). This transition has not only enhanced the performance of battery modules but also advanced the overall design and manufacturing of new energy vehicles. This article will delve into the main differences between lithium battery module FPCs and traditional wiring harnesses.

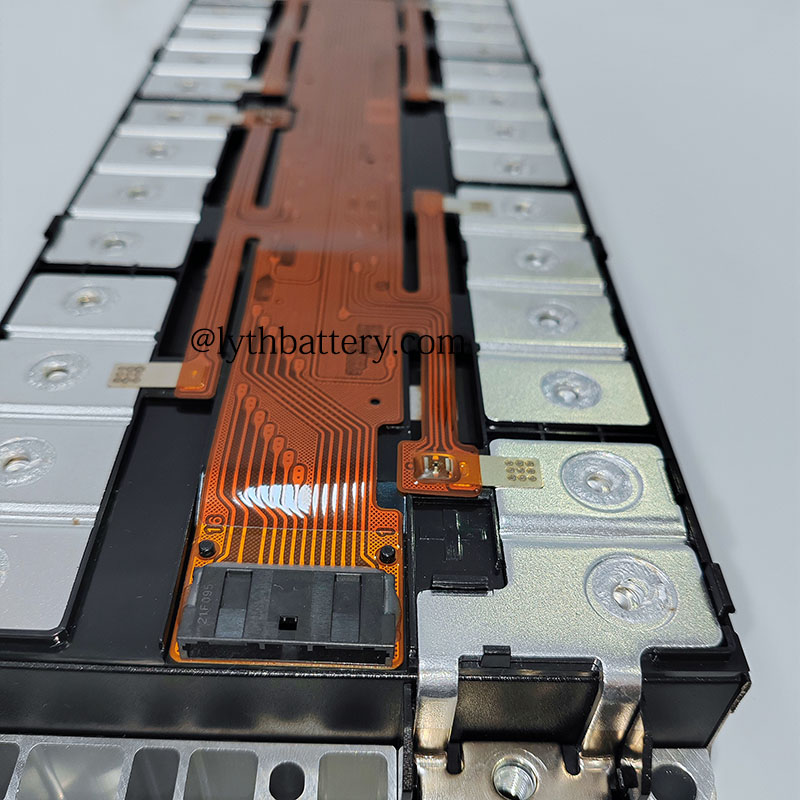

**1. High Integration and Space Utilization**

The most notable advantage of FPC solution over traditional wiring harnesses solution is their high degree of integration. FPC solution achieve tight integration of electronic components and conductive traces by printing the circuit directly onto a flexible substrate. This design greatly reduces space occupancy, allowing for the integration of more battery cells within a limited volume and increasing energy density. In contrast, traditional wiring harnesses consist of multiple wires, which not only occupy more space but also can cause confusion in complex layouts, affecting the overall performance of the battery module.

**2. Lightweight and Weight Reduction**

The lightweight nature of FPC solution is another significant advantage over traditional wiring harnesses. Due to the use of flexible substrates, FPC are much lighter than traditional wiring harnesses, which are made of metal wires and insulating materials. Reducing weight in new energy vehicles is crucial for improving energy efficiency and extending driving range.

**3. Process Flexibility and Automated Production**

FPC solutions support various processing options during production, such as ultrasonic welding and laser welding. These processes not only improve production efficiency but also ensure product quality stability. In contrast, the assembly of traditional wiring harnesses relies more on manual labor, which results in lower production efficiency and a higher likelihood of human errors. The high process flexibility of FPC makes them more suitable for automated production lines, contributing to an improved overall manufacturing level of new energy vehicles.

**4. Safety and Reliability**

Due to their excellent electrical insulation and chemical corrosion resistance, FPCs are less likely to experience safety issues such as short circuits or leakage during use. Additionally, FPCs can integrate fuse protection mechanisms that quickly cut off the circuit if abnormal current is detected, protecting the battery module from damage. On the other hand, traditional wiring harnesses may face higher failure risks in complex environments, and any issues could severely impact the performance and safety of the battery module.

In summary, traditional wiring harnesses are advantageous due to their lower cost, flexibility, and shorter customization cycles but suffer from complex wiring and poor space utilization with many soldering points; FPC offers safety and stability but come with higher costs and longer development cycles.

Please choose the appropriate connection solution based on your needs.

*********

Hot Sale Products:

Contact us for more details :

Mobile/WhatsApp/Wechat: +86 13603880312

Email: info@lythbattery.com