Categories

- Our Blog (57)

- Our Projects (62)

- FAQ (6)

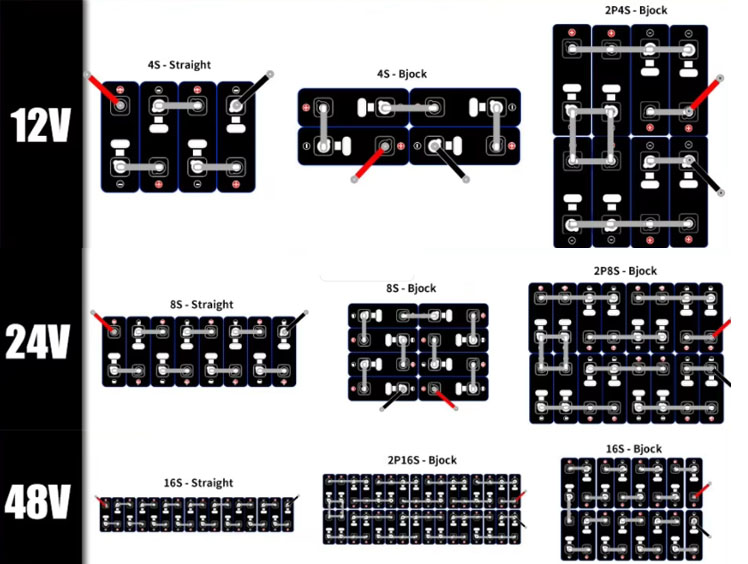

In the design of the battery modules, whether to connect them in series first and then in parallel or vice versa depends on the specific application and design requirements. In the industry, the current situation is that large-scale energy storage system often uses the series-first then parallel method, but in power applications like electric vehicle and electric bus, the parallel-first then series scheme is more commonly chosen.

Analyzing from the perspectives of system reliability, safety, and cell management (BMS) costs, both methods have their pros and cons:

1. System reliability:

Referring to the literature on the battery pack formation mode of related electric vehicles, from the perspective of the reliability of the battery pack connection and the development trend of battery voltage inconsistency and the impact of the battery pack performance, parallel first and then series connection mode is better than the series first and then parallel connection mode. Among them, in terms of system connection reliability, the reliability of first parallel then series mode is higher than that of single battery, while the reliability of series first then parallel is lower than that of single battery; in terms of battery voltage inconsistency, the voltage distribution of the grouping method of parallel fist then series is more centralized, and there are no batteries with excessively low voltage. Series first and then parallel mode, there will be more collection points, the failure rate will getting higher.

2. System safety:

For the system safety, the two main battery failure scenarios are: Open circuit and Short circuit. Short circuit are relatively extreme situations that can occur with either mode when we don’t assemble the lithium battery modules and packs properly.

In a series-first then parallel electric circuit, due to the increasing voltage during the series connection process, if one of the cell experiences the open circuit, the battery pack voltage remains unchanged, but the branch with the open-circuited cell will stop working, leading to an increase in internal resistance and a reduction in capacity. The two ends of the disconnected cell may form a high voltage and then produce arc hazards. In the parallel-first then series circuit, since the voltage does not increase during the parallel connection process, there is no arc hazard if a cell experiences the open circuit.

If the voltage difference between the two battery groups in series is relatively large and there are no suitable current limiting measures, it may lead to high current passing through and damage the battery cells.

3. Cell management (BMS)costs:

A series-first then parallel battery pack requires more sensors and wiring, with more BMS channels, resulting in higher costs. In contrast, a parallel-first then series configuration treats parallel-connected cells as one, making monitoring and BMS channels simpler and fewer, thereby reducing costs.

The specific choice should be made based on the actual application scenario and design requirements of the battery module.

—–

It can be seen from the above, series first and then parallel and parallel first and then series have their own advantages and disadvantages. Under different application conditions, it is advisable to choose the appropriate grouping method according to the capacity of the battery system, charging and discharging conditions, etc., combining with the actual application scenarios and design of the battery module.